Introduction

In various industrial applications, control cables play a crucial role in ensuring the smooth and efficient operation of machinery and equipment. However, in environments where exposure to harsh chemicals is a common occurrence, regular control cables may not be able to withstand the corrosive effects of these substances. This is where chemical resistant control cables come into play, offering a durable and reliable solution for such demanding environments.

Chemical resistant control cables are specially designed to withstand exposure to a wide range of chemicals, ensuring the integrity and functionality of the cable over an extended period. In this article, we will explore the benefits and applications of chemical resistant control cables, highlighting their importance in various industries and providing insights into their design and construction.

Understanding Chemical Resistant Control Cables

Chemical resistant control cables are engineered to withstand the corrosive effects of chemicals such as acids, alkalis, solvents, and oils. These cables are constructed using materials that offer superior resistance to chemical degradation, ensuring that the cable remains intact and functional even in highly demanding environments.

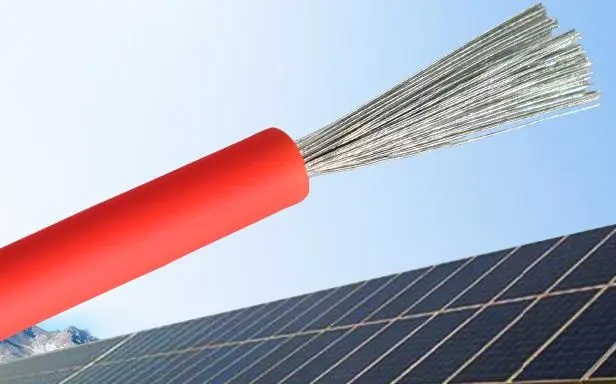

One of the key features of chemical resistant control cables is their outer sheath, which acts as a protective barrier against chemical exposure. The sheath is made from materials such as PVC, polyethylene, or fluoropolymers, which have excellent chemical resistance properties. Additionally, the conductors and insulation within the cable are also specially formulated to resist chemical attack, ensuring the overall durability and reliability of the cable.

Benefits of Chemical Resistant Control Cables

1. Enhanced Power cable for motors : Chemical resistant control cables are designed to withstand exposure to a wide range of chemicals, ensuring long-term durability and reliability in harsh environments. This enhanced durability reduces the need for frequent cable replacements, leading to cost savings for industrial operations.

2. Reliable Performance: By protecting the conductors and insulation from chemical degradation, chemical resistant control cables ensure consistent and reliable performance over time. This is crucial in industrial applications where downtime due to cable failure can result in significant losses.

3. Increased Safety: Chemical resistant control cables help maintain the integrity of electrical and communication systems in environments where exposure to chemicals is a concern. This enhances safety for personnel and equipment by reducing the risk of electrical malfunctions or failures caused by chemical damage.

4. Wide Range of Applications: Chemical resistant control cables find applications in various industries such as chemical processing, pharmaceuticals, wastewater treatment, oil and gas, and food processing. Their versatility and durability make them suitable for use in diverse environments where exposure to chemicals is a common occurrence.

Applications of Chemical Resistant Control Cables

1. Chemical Processing Industry: In chemical processing plants where exposure to corrosive chemicals is inevitable, chemical resistant control cables are essential for maintaining the integrity of control systems and instrumentation. These cables ensure reliable signal transmission and power distribution in the presence of acids, alkalis, and other chemicals.

2. Pharmaceutical Industry: Pharmaceutical manufacturing facilities require control cables that can withstand exposure to a wide range of chemicals used in the production process. Chemical resistant control cables play a critical role in ensuring the smooth operation of equipment and machinery in pharmaceutical plants, contributing to the overall efficiency and safety of the facility.

3. Wastewater Treatment Plants: Wastewater treatment facilities deal with a variety of chemicals and solvents as part of the treatment process. Chemical resistant control cables are used to connect and control pumps, valves, and sensors in these plants, ensuring efficient and reliable operation in corrosive environments.

4. Oil and Gas Industry: In the oil and gas sector, chemical resistant control cables are used in drilling rigs, refineries, and pipelines to control and monitor critical processes. These cables are designed to withstand exposure to hydrocarbons, acids, and other chemicals commonly encountered in oil and gas operations.

5. Food Processing Industry: Food processing plants require control cables that can withstand exposure to cleaning chemicals and sanitizers used to maintain hygiene standards. Chemical resistant control cables are used in conveyor systems, packaging machinery, and other equipment in food processing facilities to ensure safe and efficient operation.

Design and Construction of Chemical Resistant Control Cables

The design and construction of chemical resistant control cables are critical to their performance and reliability in harsh chemical environments. Here are some key factors to consider in the design and construction of these cables:

1. Outer Sheath Material: The outer sheath of chemical resistant control cables is typically made from materials such as PVC, polyethylene, or fluoropolymers. These materials offer excellent chemical resistance and mechanical protection, ensuring the longevity of the cable in corrosive environments.

2. Conductor Material: The conductors within chemical resistant control cables are often made from copper or aluminum, depending on the specific application requirements. These conductors are insulated with materials such as PVC, XLPE, or fluoropolymers to protect them from chemical attack and ensure reliable signal transmission.

3. Shielding: To minimize interference and ensure signal integrity, chemical resistant control cables may be equipped with shielding such as aluminum foil or braided copper. The shielding provides protection against electromagnetic interference (EMI) and radio frequency interference (RFI), enhancing the overall performance of the cable in industrial environments.

4. Temperature Rating: Chemical resistant control cables are designed to operate within a wide temperature range to suit different industrial applications. The temperature rating of the cable is determined by the insulation and sheathing materials used in its construction, ensuring optimal performance in both high and low-temperature environments.

5. Compliance Standards: Chemical resistant control cables are subject to various industry standards and regulations to ensure their quality and performance. Manufacturers adhere to standards such as UL, CSA, and IEC to certify the safety and reliability of these cables for use in industrial applications.

Conclusion

Chemical resistant control cables play a vital role in ensuring the reliability and safety of control systems in environments where exposure to chemicals is a concern. With their enhanced durability, reliable performance, and wide range of applications, these cables are indispensable in industries such as chemical processing, pharmaceuticals, wastewater treatment, oil and gas, and food processing.

By understanding the design and construction of chemical resistant control cables, industrial operators can make informed decisions when selecting cables for their specific applications. Investing in high-quality chemical resistant control cables not only ensures the longevity of control systems but also contributes to the overall efficiency and safety of industrial operations.

In conclusion, chemical resistant control cables are a valuable asset in industries where harsh chemical environments are prevalent, providing a robust and reliable solution for control and instrumentation requirements. Their importance cannot be overstated, as they contribute significantly to the seamless operation of machinery and equipment in challenging industrial settings.